Liquid Check Valves - Is A Backwater Valve The Same As A Check Valve?

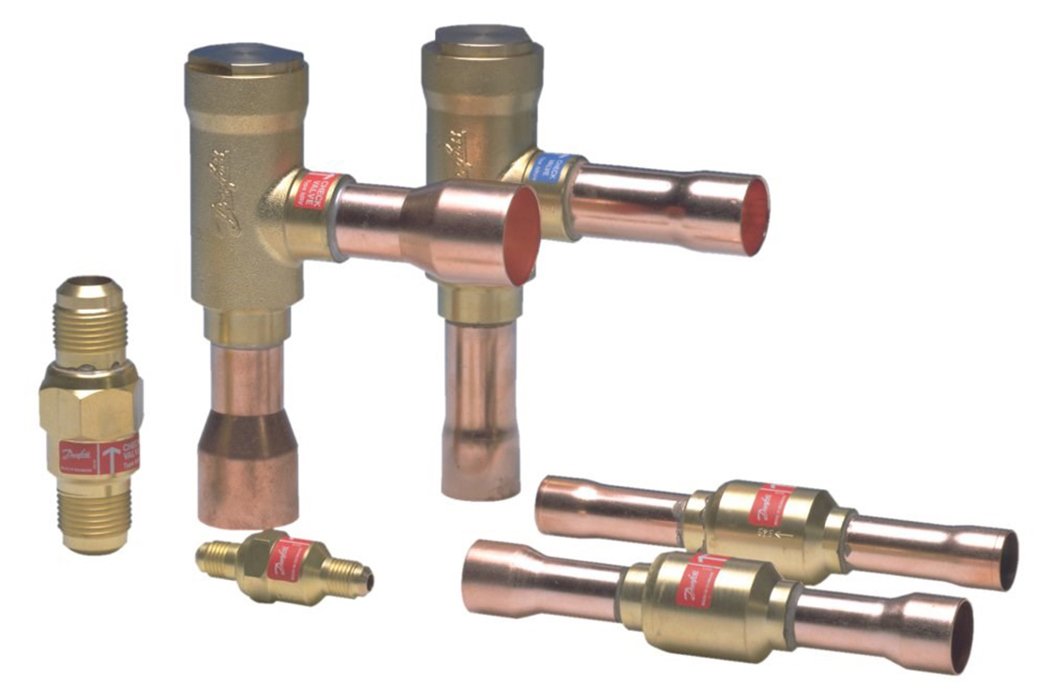

Liquid check valves

How They Differ: Check Valve vs Backwater Valve. The two valves are similar mechanisms with slightly different approaches to preventing backflow. A check valve is usually used to prevent liquids from contaminating a clean water supply, for example. A backwater valve is often intended to protect your sewage line, though

Where do you put a check valve on a water pump?

In submersible pump applications, the first check valve should be installed directly on the discharge head of the pump or maximum one pipe length (20 feet) above pump. Water pumped and flowing through a piping system has a certain amount of energy (weight x velocity).

How often do check valves fail?

While typical component lifespans are application specific, manufacturers suggest metal and plastic check valves should be replace every 5-7 years whereas check valves manufactured from rubber may remain fully serviceable for up to 35-50 years.

How much pressure can a check valve hold?

Most spring-loaded check valve manufacturers offer limited options for cracking pressures; however, Check-All Valve offers spring cracking pressures from 1/8 PSI to upwards of 85 PSI (and virtually anywhere in between).

Do you need a check valve on water line?

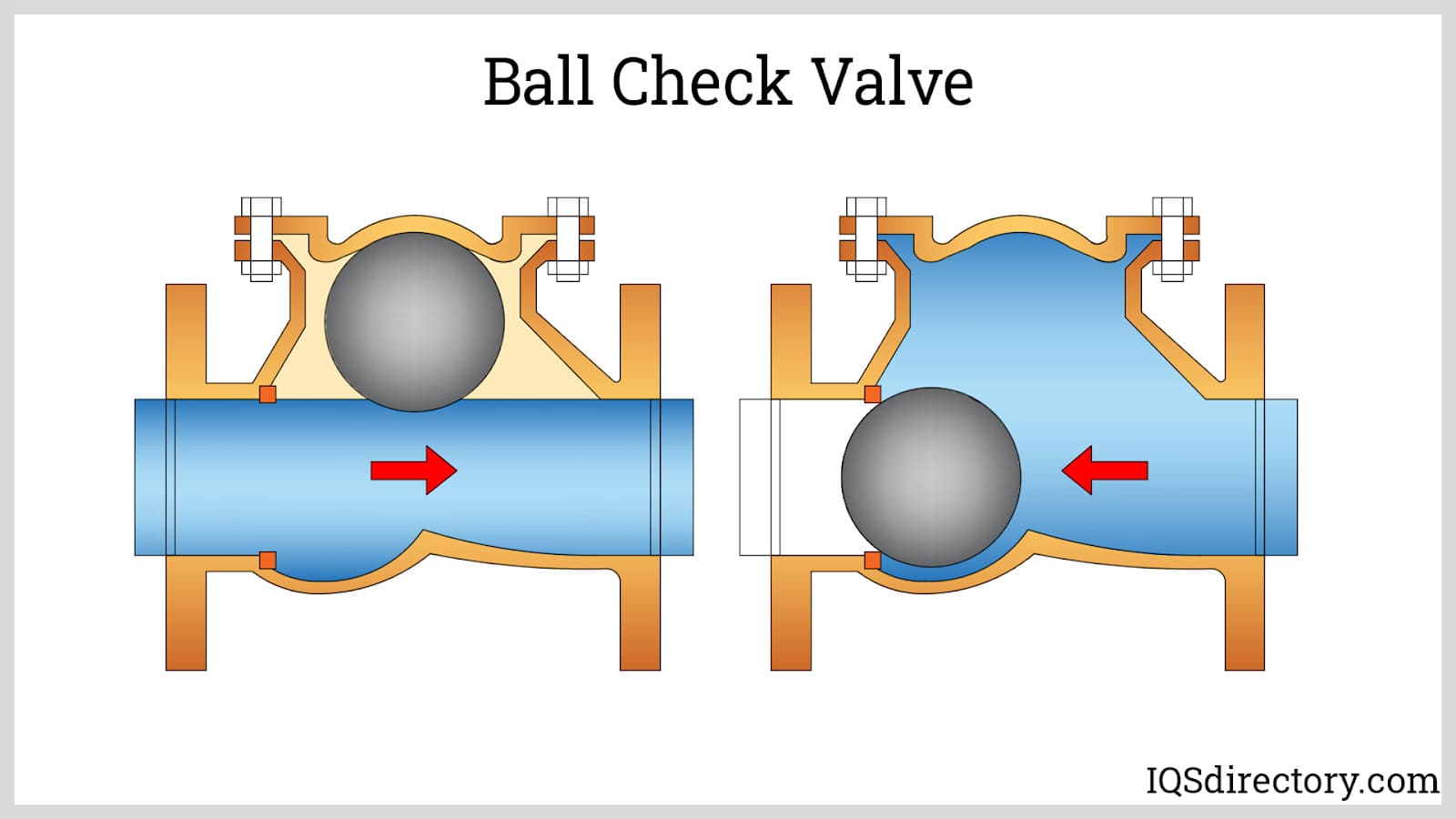

Water check valves are designed to allow water to flow only in one direction. They are required in all submersible pump installations since they keep water from draining back into the well when the pump is shut off. Check valves help prevent a few undesirable conditions in systems.

How reliable are check valves?

Experience indicates that check valves are prone to failure and that they may fail undetected. Therefore, the conservative assumption is that check valves may be listed in process hazard analyses as safeguards, but they are rarely considered to meet the standards required of an independent protection layer (IPL).

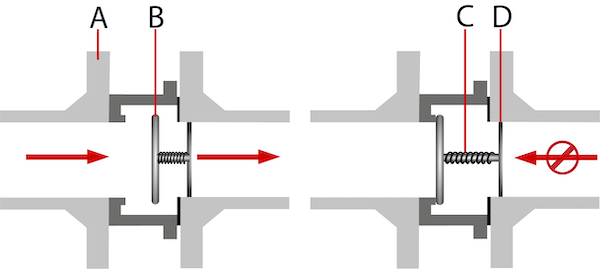

What does the arrow on a check valve mean?

An arrow stamped on the outside of the valve body indicates the direction of flow. Check valves may be classified as swing check valve and lift check valve.

Can a check valve get clogged?

Debris in pipeline — Debris in the piping can get lodged in the check valve, causing it to remain stuck in the open or closed position. Plus, rapidly traveling debris can affect the one-way check valve and damage the internal mechanism.

Are two check valves better than one?

Using a second check valve just in case the one on the pump fails is never a good idea. If the check on the pump fails, it must be replaced. Having a second check valve will only mask the problem of the first check valve, and cause water hammer and possible contamination in the process.

How can you tell if a check valve is bad?

The signs of a failing swing check valve are often audible. When the disc opens and closes repeatedly (because of low-pressure flow) or violently (because of water hammer), it emits a tapping or hammering sound, respectively.

What are 3 types of check valves?

The three main types of check valves we offer are ball, piston, and stop check valves.

Do check valves restrict water flow?

Also known as non-return valves, one-way valves, or backflow preventers, check valves prevent flowing media from flowing back upstream.

Which is better spring check valve or swing check valve?

Since spring check valves are functional in vertical applications, they offer significantly more versatility than swing check valves, and are much more likely to fit with preexisting piping configurations. Depending on the spring selection, this type of valve will work well in virtually any flow orientation.

Do check valves reduce water pressure?

Check valves do not reduce pressure, they actually help maintain it. In the setup you describe, it might work. However you will DEFINITELY need another check valve on the outlet of the tank to prevent the high pressure flow from backwashing in through the bottom, since there is no shuttoff/float valve there.

What is a poppet check valve?

Home » What is a Poppet Check Valve? A poppet check valve incorporates a disc (normally at the end of a “sleeve” or “stem”) utilized as the checking mechanism. It is often spring loaded to help close the valve prior to fluid flow reversal. This eliminates the hydraulic shock also known as water hammer.

Where should a check valve be installed?

Check valve can be installed in horizontal or vertical piping runs, with the flow running upward. Mounting for vertical installations is critical.

What is the other name of check valve?

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction.

Do PVC check valves restrict flow?

Yes they do as that is their purpose. They restrict the flow in one direction 100%. in the reverse direction (open) they will never get to 100& flow as it takes a small amount of effort to shift the valve from the blocked direction to the flow direction.

Can a check valve replace a backflow preventer?

check valves. And we clear up a misconception that's often inquired about in online forums: while check valves have other important applications, they cannot be considered a safe substitute for backflow preventers when it comes to protecting the purity of drinking water.

Why is my check valve leaking?

Valves can leak for a variety of reasons, including: The valve is not fully closed (e.g., due to dirt, debris, or some other obstruction). The valve is damaged. Damage to either the seat or the seal can cause leakage.

Post a Comment for "Liquid Check Valves - Is A Backwater Valve The Same As A Check Valve?"