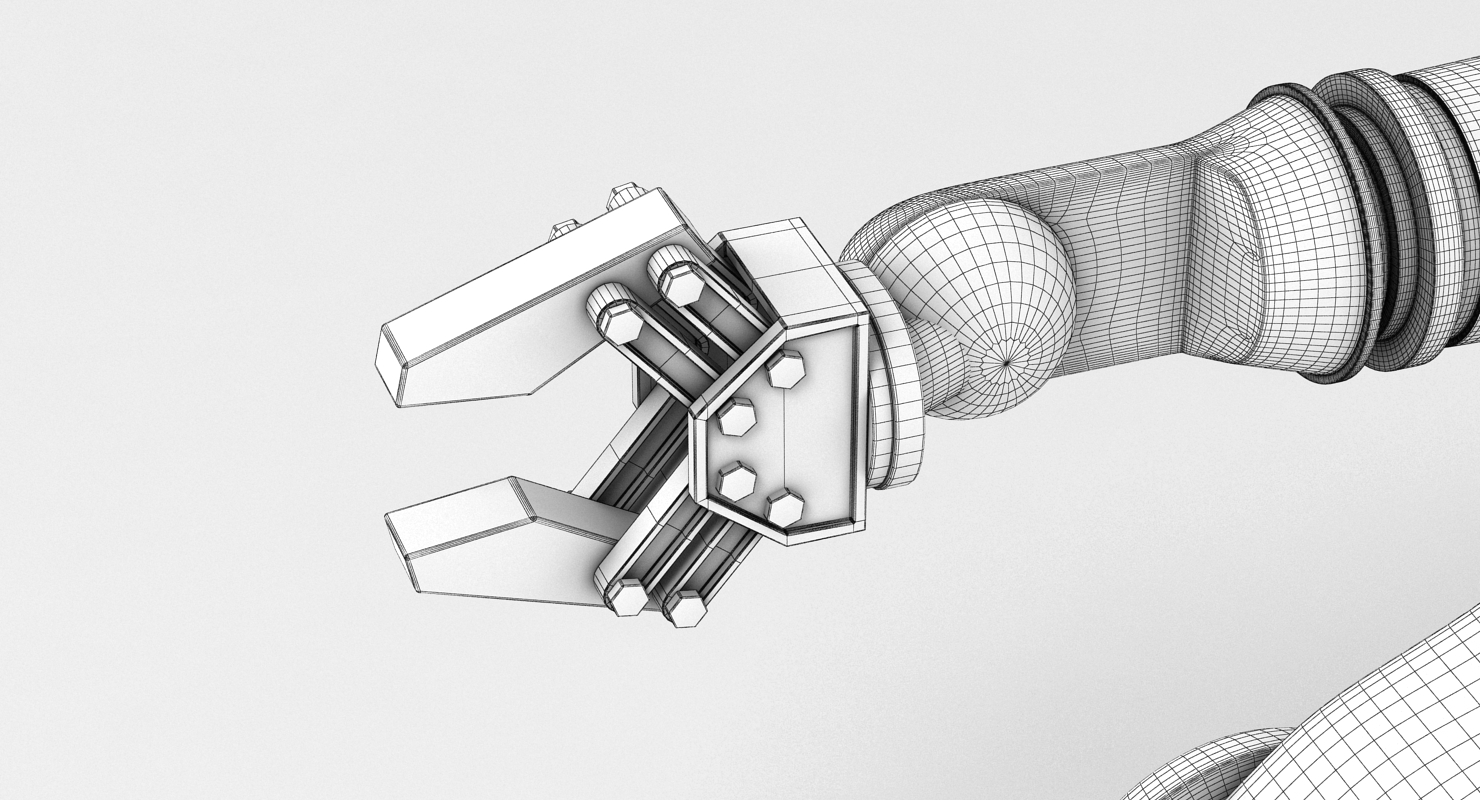

Simple Robot Arm Design - How Do You Make A Homemade Robotic Arm?

Simple robot arm design

DIY Robotic Arm

- Step 1: Required Components. 2 sheets of acrylic or wood with dimensions 30*50 cm.

- Step 2: Designing the Parts.

- Step 3: Assembly.

- Step 4: Motor Selection.

- Step 5: Torque Analysis.

- Step 6: Wiring.

- Step 7: The Programming.

- Step 8: The Final Shape.

Which robots use an XYZ coordinate system?

Cartesian robots, which are also called linear robots or gantry robots, are industrial robots that work on three linear axes that use the Cartesian Coordinate system (X, Y, and Z), meaning they move in straight lines on 3-axis (up and down, in and out, and side to side).

How much does a robotic arm cost?

Typically, an industrial robotic arm will cost anywhere between $25,000 and $400,000. However, total device costs could increase once other device specs are added.

IS robotics easy?

The robotics world is as difficult as can be. However, with a passion to master the unknown and the complex, learning robotics should come easy even in your adult years. Given below are some reasons why you could start learning robotics right away.

Is drone a robot?

Essentially, a drone is a flying robot that can be remotely controlled or fly autonomously using software-controlled flight plans in its embedded systems, that work in conjunction with onboard sensors and a global positioning system (GPS). UAVs were most often associated with the military.

What are the 3 main challenges in robotics?

Three challenges focus on fundamental problems in robotics: developing robot swarms, improving navigation and exploration, and developing artificial intelligence that can “learn how to learn”, and use common sense to make moral and social decisions.

What do I need to build my own robot?

What Tools and Materials Do You Need to Build a Robot?

- Cameras.

- Motors.

- Servos — sensors or guides for movement.

- The robot's brain or “microcontroller” — this could be a Raspberry Pi affordable, compact development processor board, which is the size of a credit card — or a similar device.

What is inside a robot arm?

Most industrial robotic arms use four to six joints, which provide the same number of axes of rotation for movement. In addition to rotary joints, robotic arm components include the robot controller, an end-of-arm tool, actuators, sensors, vision systems, power systems, and software components.

How many axis can a robot have?

Most industrial robots utilize six axes, which give them the ability to perform a wide variety ofindustrial tasks compared to robots with fewer axes. Six axes allow a robotto move in the x, y, and z planes, as well as position itself using roll, pitch, and yaw movements.

What are the 4 types of robotic arm designs?

Types of robotic arms

- Articulated arm.

- Six-axis.

- Collaborative robot.

- SCARA.

- Cartesian.

- Cylindrical.

- Spherical/Polar.

- Parallel/Delta.

How accurate is a robotic arm?

Despite tight machining tolerances, good mechanical design, and careful assembly, robotic arms typically exhibit average Cartesian positioning errors of several millimeters. Fortunately, the vast majority of this error can be removed in software by proper calibration of the so-called "zero-offsets' of a robot's joints.

How strong are robotic arms?

The strongest industrial robot arm is the M-2000iA/2300 Super Heavy Payload Robot made by the Fanuc Corporation (JPN). It is a six-axis robotic arm which can pick up and move objects weighing as much as 2,300 kg (5,070 lb).

Can robots be waterproof?

Because both ROV and AUV robots contain computers and electronic equipment, underwater robots need to be waterproof. This means that water cannot damage the equipment because it is inside a covering that prevents water from coming in.

What is a robot arm called?

Mechanical arms are composed of multiple beams connected by hinges powered by actuators. One end of the arm is attached to a firm base while the other has a tool. They can be controlled by humans either directly or over a distance. A computer-controlled mechanical arm is called a robotic arm.

What makes a good robotic arm?

Speed and accuracy Accuracy is an important consideration if the robot arm have to interact with small parts or tiny items. A robot repeatability (how well the robot can reproduce the same move in unchanged conditions) will be an important criteria during a pick and place task in a laboratory.

How do I build a robot?

You can use an ultrasonic sensor to build an obstacle avoiding robot or line sensor to build a line

How do you make a robot that moves and talks at home?

- Step 1: Things You Need. Collect the following items.

- Step 2: Breadboard Test. First, we make the circuit on the breadboard and test it.

- Step 3: Play Sounds From Arduino.

- Step 4: Robotic Voice.

- Step 5: Convert Your Voice.

- Step 6: Testing the Functionallity.

- Step 7: Making the Mask.

- Step 8: Soldering.

What is the easiest robot to make?

From our research, The Bristlebot is one of the easiest and most fun beginner robots to make. ... The Bristlebot

- one toothbrush;

- one vibrating motor;

- one battery;

- some double-sided adhesive tape;

- a pair of pipe cleaners;

- a pair of googly eyes.

How many types of robotic arms are there?

Other Robotic Arms - Other types of robotic arms are less common than the ones mentioned above. These include cartesian, SCARA, cylindrical, and polar. Cartesian robotic arms feature three linear axes that are located at right angles to one another for straight line movement.

How do robots move?

Robots spin wheels and pivot jointed segments with some sort of actuator. Some robots use electric motors and solenoids as actuators; some use a hydraulic system; and some use a pneumatic system (a system driven by compressed gases).

Post a Comment for "Simple Robot Arm Design - How Do You Make A Homemade Robotic Arm?"